Researchers employ common plastics to kickstart radical chain reactions, creating a way to reuse plastic waste while improving process safety and efficiency.

Artistic depiction of extremely reactive molecules called radicals being generated from plastic fibers. (Illustration: Koji Kubota and Hajime Ito)

Single-use plastics are a major environmental concern, but now, rather than being disposed of as garbage, used plastic bags from the grocery store could be utilized to carry out a reaction that can detoxify hazardous chemicals.

A team led by researchers at the Institute for Chemical Reaction Design and Discovery (WPI-ICReDD), Hokkaido University has developed a method that uses common plastic materials instead of potentially explosive compounds to initiate radical chain reactions. This approach significantly increases the safety of the process while also providing a way to reuse common plastics such as polyethylene and polyvinyl acetate. These findings have been published in the Journal of the American Chemical Society.

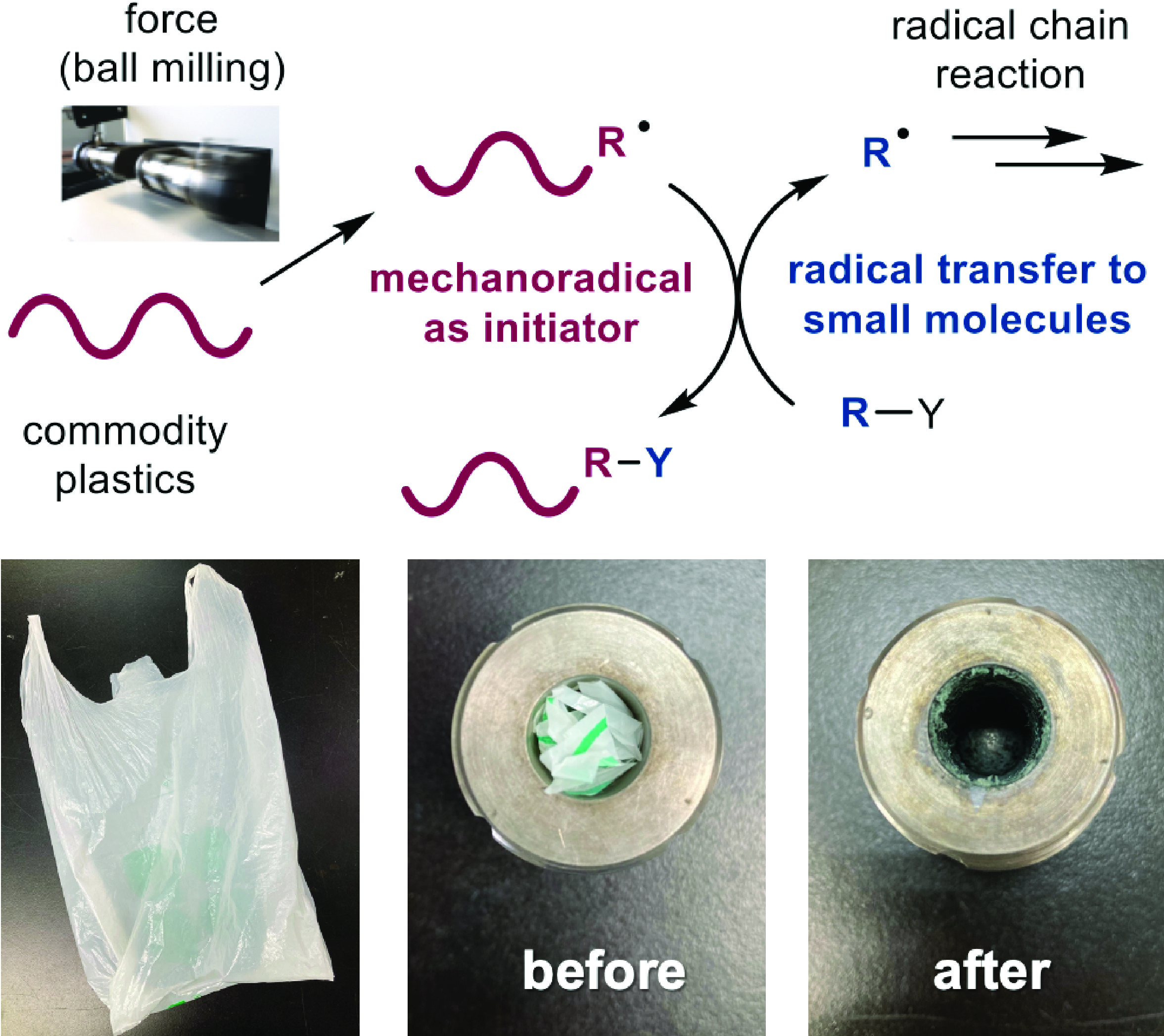

Researchers utilized a ball mill, a machine that rapidly shakes a steel ball inside a steel jar to mix solid chemicals. When the ball slams into the plastic, the mechanical force breaks a chemical bond to form radicals, which have a highly reactive, unbonded electron. These radicals facilitated a self-sustaining chain reaction that promotes dehalogenation— i.e., the replacement of a halogen atom with a hydrogen atom—of organic halides.

“The use of commodity plastics as chemical reagents is a completely new perspective on organic synthesis,” said Associate Professor Koji Kubota. “I believe that this approach will lead to not only the development of safe and highly efficient radical-based reactions, but also to a new way to utilize waste plastics, which are a serious social problem.”

(Top) General scheme for using mechanical force to trigger a radical chain reaction. (Bottom) Shreds of a grocery bag were utilized to initiate a reaction in a ball mill jar. (Koji Kubota, et al. Journal of the American Chemical Society. December 22, 2023)

The reuse of waste plastic was demonstrated by adding plastic shreds of a common grocery bag to the ball mill jar and successfully carrying out the reaction. The team also showed their method could be applied to the treatment of highly toxic polyhalogenated compounds, which are widely used in industry. Polyethylene was employed to initiate a radical reaction that removed multiple halogen atoms from a compound commonly used as a flame retardant, thus reducing its toxicity.

Researchers anticipate this method will garner the attention of industry due to advantages in cost and safety.

“Our new approach using stable, cheap and abundant plastic materials as initiators for radical chain reactions holds the significant potential to foster the development of industrially attractive, safe and highly efficient chemical processes,” commented Professor Hajime Ito.

Associate Professor Koji Kubota (left) and Professor Hajime Ito (right) of the research team at the Institute for Chemical Reaction Design and Discovery (WPI-ICReDD), Hokkaido University. (Photo: WPI-ICReDD)

Original Article:

Koji Kubota, Julong Jiang, Yuri Kamakura, Reon Hisazumi, Tsubura Endo, Daiyo Miura, Shotaro Kubo, Satoshi Maeda, Hajime Ito. Using Mechanochemistry to Activate Commodity Plastics as Initiators for Radical Chain Reactions of Small Organic Molecules. Journal of the American Chemical Society. December 22, 2023.

DOI: 10.1021/jacs.3c12049

Funding:

This work was supported by the Japan Society for the Promotion of Science (JSPS) KAKENHI grants (22H00318, 21H01926, 22K18333, 22H05328); the Japan Science and Technology Agency (JST) CREST grant (JPMJCR19R1), and FOREST grant (JPMJFR201I); and the Institute for Chemical Reaction Design and Discovery (ICReDD), which was established by the World Premier International Research Initiative (WPI), Ministry of Education, Culture, Sports, Science and Technology (MEXT) of Japan.

Contacts:

Associate Professor Koji Kubota

Graduate School of Engineering;

Institute for Chemical Reaction Design and Discovery (WPI-ICReDD)

Hokkaido University

Tel: +81-11-706-6561

Email: kbt[at]eng.hokudai.ac.jp

Professor Hajime Ito

Graduate School of Engineering;

Institute for Chemical Reaction Design and Discovery (WPI-ICReDD)

Hokkaido University

Email: hajito[at]eng.hokudai.ac.jp

Collin Stecker (Public Relations and Outreach)

Institute for Chemical Reaction Design and Discovery

Hokkaido University

Tel: +81-11-706-9646

E-mail: public_relations[at]icredd.hokudai.ac.jp

Sohail Keegan Pinto (International Public Relations Specialist)

Public Relations & Communications Division

Office of Public Relations and Social Collaboration

Hokkaido University

Tel: +81-11-706-2186

Email: en-press[at]general.hokudai.ac.jp

Related Articles:

Birch reduction simplified to a one-minute mechanochemical process

Customizing catalysts for solid-state reactions

120-year-old reaction turned on its head with environment-friendly, paste-based method

New method makes generic polymers luminescent

Toward overcoming solubility issues in organic chemistry

Mechanical force as a new way of starting chemical reactions

留言 (0)